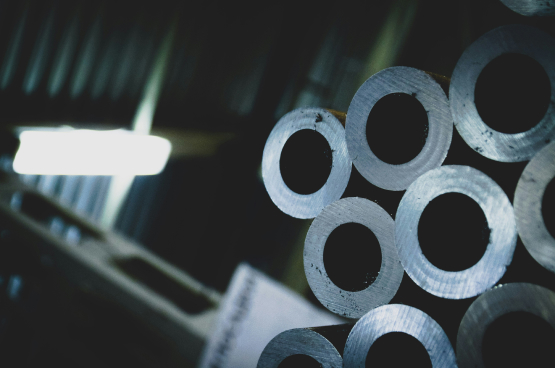

The Importance of Selecting Raw Materials

The raw materials you choose in the design process of your product can make or break its future.

Many of the reasons for this are obvious. Poor quality raw materials can, of course, impact the longevity of your product and the efficacy of your design. Unreliable suppliers may cause costly backlogs and failures to meet demand, while materials sourced from overseas may appear to offer cost-savings, yet hidden, expensive shipping costs may eat into these cost savings.

But even if manufacturers find cost-effective, high-quality materials from a reliable supplier, you might find that this isn’t enough for today’s aware consumer. Increasingly, buyers are making purchasing decisions based on sustainability issues — an area where supply chains face heightened scrutiny.

To ensure the longevity of your product and your brand, it’s critical that product design teams consider these issues at the procurement stage, offsetting risks that may emerge later. For that, a concrete process in selecting raw material suppliers is valuable. We’ve detailed ours below.

Our 3-Step Process

At ISTEC, we understand the nuance of sourcing raw materials that fit every requirement. In our projects, we apply the following three-step process to assist clients in sourcing raw materials that fit the bill.

1: Identify Potential Suppliers

Our process begins with a comprehensive analysis performed by our team to identify suppliers. At this stage, we generate a report that we present to our customers of viable options, researching a wide range of criteria, including sustainability, location, price, shipping factors, and delivery times.

At this stage, we also consider top-level sustainability practices, awards, accreditations, demonstrations of ethical labor conditions, and more. If additional factors are important to the product (such as lead times, storage requirements, processing factors, etc.), then we will include these in our initial research stage.

2: Vetting and Selecting Suppliers

Once we’ve shortlisted a group of suppliers, it’s time for our in-depth vetting process to begin in earnest. In this second stage, we perform additional research to identify issues we may have overlooked in our cursory primary research phase.

Our rigorous vetting process looks into issues such as suppliers’ financial health to ensure viability in the long term, environmental impacts of their actions, including any damaging press or reports, and references from other sources to verify the supplier’s reputation.

Ultimately, this stage encourages a dialogue between your team and the supplier, helping you decide on crucial factors and discussing the possibilities for your product and manufacturing processes.

3: Building Relationships and Ensuring Transparency

Once we’ve shortlisted a group of suppliers, it’s time for our in-depth vetting process to begin in earnest. In this second stage, we perform additional research to identify issues we may have overlooked in our cursory primary research phase.

Our rigorous vetting process looks into issues such as suppliers’ financial health to ensure viability in the long term, environmental impacts of their actions, including any damaging press or reports, and references from other sources to verify the supplier’s reputation.

Ultimately, this stage encourages a dialogue between your team and the supplier, helping you decide on crucial factors and discussing the possibilities for your product and manufacturing processes.

Sourcing Your Own Raw Materials? We Can Help

Whether you’re creating a new product or making changes to your manufacturing process, the experienced team at ISTEC can help you source raw materials that meet your objectives.

From strengthening an ethical supply chain to sourcing bespoke materials that align with your product’s unique needs, our expert team can guide you through it all, using our network of connections and vetting process.

For support on sourcing raw materials, manufacturing, or any other aspect of bringing your new product to market, contact our team here for a personalized consultation.