Product design and development is by far the most complex of the services we offer. Design divides opinion, and although, we are not proposing the next showpiece at the Louvre, it does require 10+ people to agree upon a single product design.

Agreeing a design can be unbelievably challenging, consequently, we designed a process to guide us through the product design phase.

Our Product Design and Development Process:

- Research

- Conceptualize

- Prototyping

- Cost Estimation and Budgeting

Still unsure? Let’s take a further look at our design process through the lens of creating a new spreader – one of our first successes!

Research - The making or breaking of the NPD

The research phase of design and development is the most important step. The research phase is a combination of communication with our partners who have sanctioned the project and intense online research to understand:

- What is already out there in the marketplace?

- What are end customers looking for?

- What are the requirements of our partners for this project?

- How can we set ourselves apart from the rest of the marketplace?

In our spreader example, we are looking to establish ourselves in the European and USA pedestrian spreader markets.

USA-made products have long been the industry standard. But as competition from Chinese manufacturers entered the marketplace, prices have been driven low and standards are slipping

Many spreader providers are moving their production East but are being hit with charges of up to 25% duty.

Customers are frustrated. They want consistency and a return to a great product at a competitive price.

The marketplace is also very stagnant. No new technology has been implemented for over 30 years.

What has our research concluded?

We need a functional spreader range that focuses on quality at a competitive price. It must be innovative in design to help establish ourselves quickly as the progressive spreader manufacturer.

Some countries are hit with heavy duties in our industry. We should look for a supply chain that bypasses these tariffs, enabling us to provide a great value proposition.

What Next?

Once we answer these questions, we create a specification sheet for the new product range based on the following criteria.

- Functionality

- Aesthetics

- Price

In doing so, we present a thorough understanding of the end goal we are trying to achieve and we enable the next phase of the design process – Conceptualization.

Conceptualize

Get ready for some fun here! You’ll be viewing some beautiful drawings and receiving the very first images of your new product.

The hard yards of research have put us in a fantastic position to create a brilliant pedestrian spreader range. We understand the needs of the end users and the needs of our partners. Furthermore, we have a blueprint for a product we can use to begin our creative process.

Now it’s time to brainstorm, create preliminary sketches, and develop a design that balances aesthetics, functionality, ergonomics, and manufacturability. We will create a product that is not only appealing to consumers in price, looks, and usability but also feasible to manufacture.

Multiple Options for you to choose from

We will present multiple options hitting different price points that suit the market. The design team will brief your account manager and they will present all our work to you.

Materials Selection

One thing we will be working on in the background at this point will be materials selection. A product can look great but if they’re not of the right specification to endure the rigors of spreading salt in winter, our product will fall to pieces and our brand will die a quick death!

Just as important as the quality of the materials is the location from where they are sourced. Every international freight adds great expense to the product and carbon dioxide to the environment.

Our primary goal is to find high-quality, locally sourced materials.

We will ensure the materials used are of suitable durability, easily accessible for our purchasing team, and within the price parameters set.

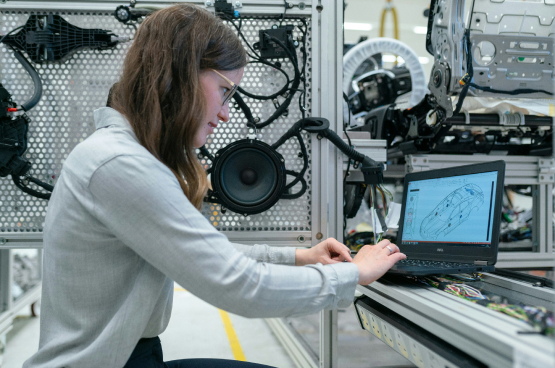

Brainstorm with the Account Manager & Lead Designer

It’s the account manager’s job to bring you and our design team together to choose the best option for success.

Maybe the first set of drawings was not what you had in mind. Perhaps you love the expensive option but want to know if you can reduce the price in any way.

Whatever you desire, your account manager will help bridge the gap between idea and concept. The more feedback you give, the better our account manager can liaise with the design team.

Sign Off on Designs for Prototyping

So, we know everything there is to know about the pedestrian spreader market, and we understand your requirements.

We’ve gone to our brainstorming temple and delivered a fantastic set of drawings providing multiple options for your new spreader. You like one so much, you think that’s the one for you. What next?

Once we sign-off on the drawings, we begin the prototyping process.

Prototyping

Your account manager will give you a turnaround time for completion and you will soon receive a prototype ready to test in the marketplace.

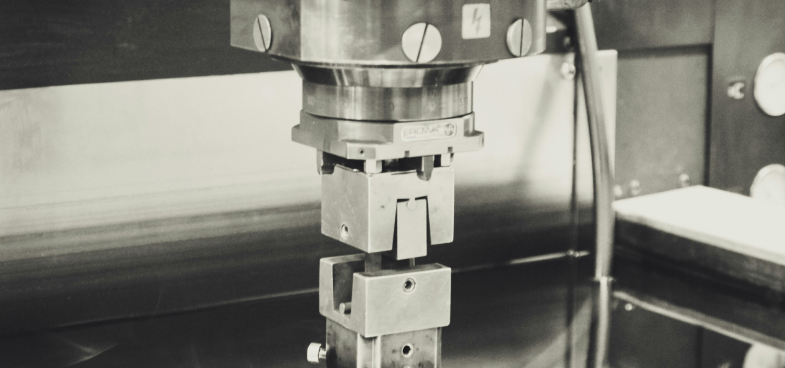

We will also retain a prototype to run tests ensuring the product is up to scratch.

Cost Estimation and Budgeting

While testing of the prototype is being carried out, our team will be working hard to offer the most accurate cost estimations of the final product.

This is the final phase of our new product design and development process and is of the utmost importance.

Both you, our account manager, and our design team have put in a huge amount of work to get to this point. We need to make sure our cost estimations are as accurate as possible, our budget is fixed and our timeline realistic.

Errors in this phase will lead to a disconnect in the expectations of our customers and what we can delive.

To ensure we are accurate, we follow these steps religiously;

- Suppliers sign off on commitments to prices

- Historical data on shipping costs and current shipping quotes are factored into a transport of materials goods estimation

- Assembly processes and timings are evaluated

- Start up costs including moulds and jigs are agreed with suppliers.

- Signatures are acquired by all stakeholders to agree upon timelines

- Contracts are written up and agreed with suppliers.